Aeration System

Essential in all biological wastewater treatment plants

Glanua’s Aeration System is essential in all biological wastewater treatment plants to provide oxygen to bacteria for treating and stabilising the wastewater. Oxygen is needed by the bacteria to allow biodegradation to occur. The supplied oxygen is utilised by bacteria in the wastewater to break down the organic matter containing carbon to form carbon dioxide and water. In order to achieve effective biodegradation of the effluent diffused aeration systems must be installed. Glanua have over 25 years’ experience in the supply of Aeration Systems in all types of wastewater applications.

Bubble Diffused Aeration Systems

Further to biological aeration systems we can provide coarse bubble diffused aeration systems suitable for balancing, mixing and sludge management applications. Glanua provides a full turn-key solutions including, aeration design, fabrication, installation and commissioning for Aeration Systems on all wastewater applications.

Glanua can provide all components to Fine Bubble Diffused Aeration Systems including:

- Air Blowers and associated instrumentation

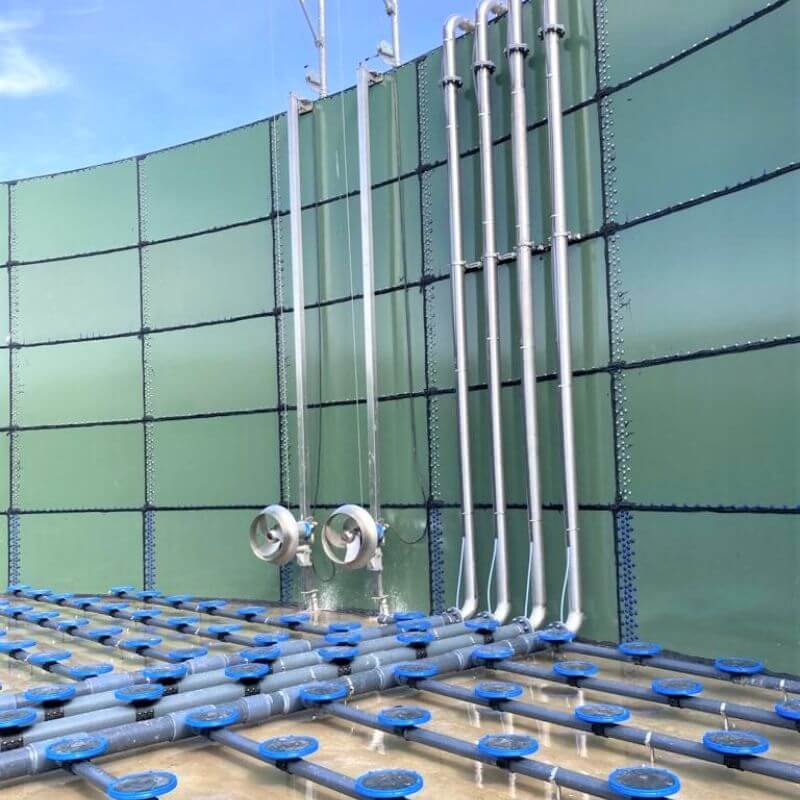

- Design and fabrication of stainless steel air delivery manifold including instrumentation

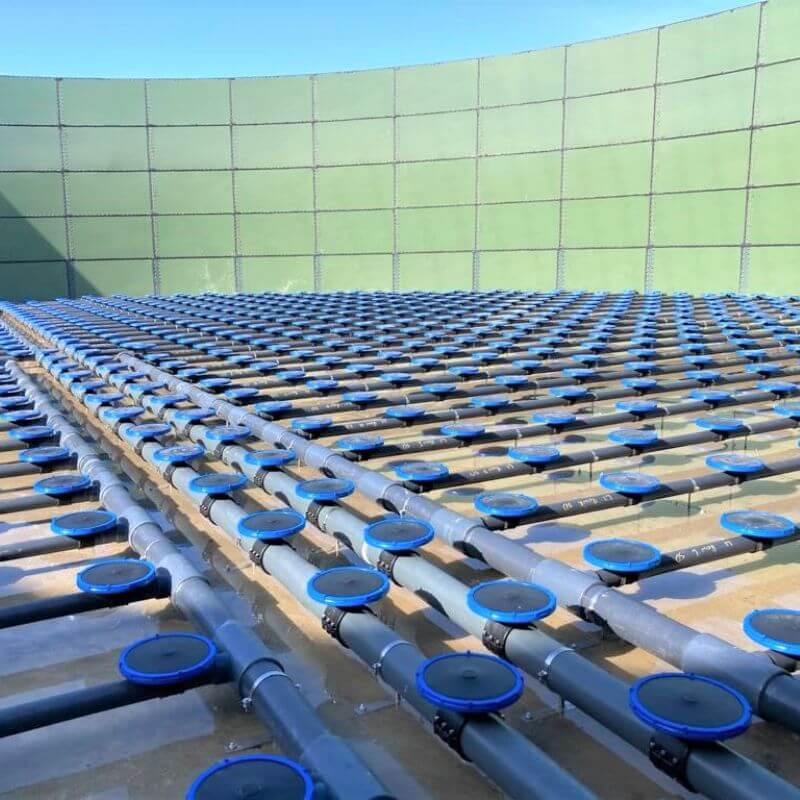

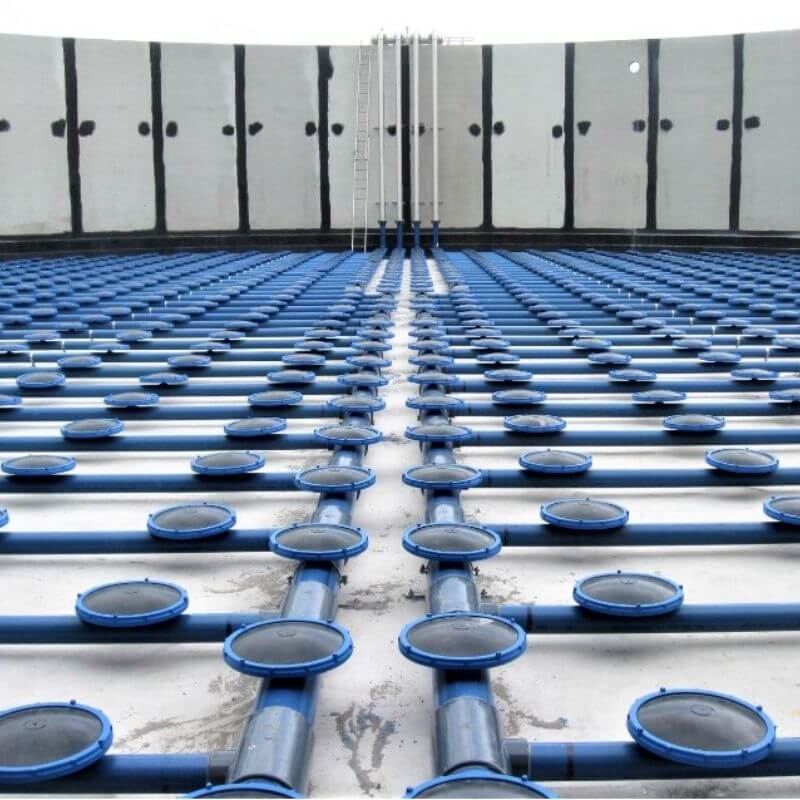

- Diffuser selection, off site fabrication of diffuser grid

- Platforms and support structures

- Installation and commissioning

Key Components:

- Highly efficient Blower selection and supply including VSDs and DO system for control and efficiency

- Stainless Steel aeration feed manifold including air flow meter and pressure instrumentation including valving

- Fixed fine bubble diffused aeration grid or lift out fine bubble diffused aeration grid

- Selection and provision of high efficiency diffusers including tube type, disc type or coarse bubble, depending on client’s needs

- All aeration components can be integrated into the existing main control panel and/or Glanua can provide a local control panel including HMI/ PLC using a PID loop to control aeration via DO instrumentation

Benefits of the Glanua’s Aeration System:

- Full turn-key solution including, design, fabrication, installation and commissioning

- Energy Efficient solution for aeration needs

- Glanua are experts in aeration retrofit projects

- Glanua’s aeration systems are designed and fabricated to the client’s site requirements, giving a bespoke, turn-key solution for aeration needs

- We can provide both disc or tubular type diffusers to meet the highest energy efficiency requirements and a range of membrane options such as PTFE and EDPM to accommodate corrosive or high pH effluent systems

Key Components:

- Highly efficient Blower selection and supply including VSDs and DO system for control and efficiency

- Stainless Steel aeration feed manifold including air flow meter and pressure instrumentation including valving

- Fixed fine bubble diffused aeration grid or lift out fine bubble diffused aeration grid

- Selection and provision of high efficiency diffusers including tube type, disc type or coarse bubble, depending on client’s needs

- All aeration components can be integrated into the existing main control panel and/or Glanua can provide a local control panel including HMI/ PLC using a PID loop to control aeration via DO instrumentation

Benefits of the Glanua’s Aeration System:

- Full turn-key solution including, design, fabrication, installation and commissioning

- Energy Efficient solution for aeration needs

- Glanua are experts in aeration retrofit projects

- Glanua’s aeration systems are designed and fabricated to the client’s site requirements, giving a bespoke, turn-key solution for aeration needs

- We can provide both disc or tubular type diffusers to meet the highest energy efficiency requirements and a range of membrane options such as PTFE and EDPM to accommodate corrosive or high pH effluent systems

Typical Installations

Fixed Aeration System

Fixed aeration grids are an excellent choice where down time can be accommodated for maintenance such as where dual-stream or multi- stream aeration lanes exist. These systems are designed to give optimum floor coverage for effective mixing while also providing for efficient oxygen transfer to the biomass.

Lift Out Aeration System

Lift-out diffused aeration systems provide a superior choice for ongoing operation and maintenance flexibility. These grids can be removed from in-service tanks for periodic cleaning or maintenance while still maintaining aeration with adjacent grid(s). These systems are designed to provide optimum operator flexibility and zero downtime while still maintaining highly efficient aeration capability.