Boherbue Wastewater Treatment Plant Upgrade

Key Information

Project Value €/£

€6.5 Million

Client

Irish Water

Duration

33 Months

Location

North West, Co. Cork

Sector

Wastewater

Project Overview

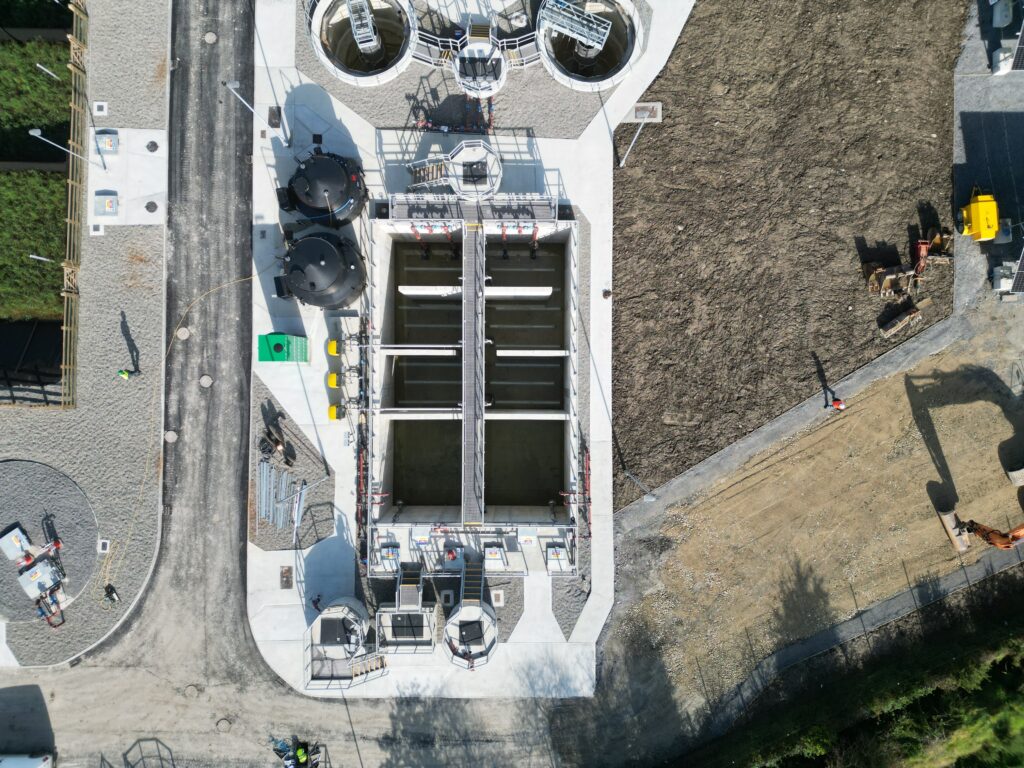

The upgrade of Boherbue WwTP is a great example of how Glanua together with our client, Uisce Eireann are using innovative and sustainable solutions to cut carbon emissions. Under the collaborative Early Contractor Involvement (ECI) framework, the plant uses cutting-edge technology to treat wastewater and will include solar technology and natural sludge drying reed beds to significantly improve the sustainability of the Boherbue plant. The project will also reuse existing constructed wetlands to maintain vital animal and plant habitats.

The existing Boherbue Sewerage Scheme is composed of a partially combined collection network (including three forwarding pumping stations (PSs) conveying sewage to an 800 PE wastewater treatment plant (WwTP). The WWDL granted by the EPA to Irish Water in June 2013, has set the discharge ELV’s for this project. The Boherbue WwTP discharges to constructed wetlands north of the plant and secondary treated effluent to the River Brogeen, north of the site. The existing WwTP includes the following treatment stages:

- Storm separation by overflow chamber

- Preliminary treatment (Screening)

- Primary treatment using Imhoff Tanks

- Secondary treatment using trickling filters and humus tanks

- Tertiary treatment using an Integrated Constructed Wetland

- Sludge treatment using a sludge holding tank

Due to the agglomeration growth, the WWTP is failing to meet the treatment standards specified in its current Wastewater Discharge Licence (WWDL).

The purpose of the Boherbue Sewerage Scheme is to provide a new wastewater treatment plant catering for the future agglomeration load.

Our Approach

Odour Control

Glanua adopts a proactive approach to mitigate odour concerns in the proposed Boherbue Wastewater Treatment Plant (WwTP). To prevent the outward diffusion of pollutants during treatment, we prioritize the implementation of a passive ventilation system at critical points within the plant. This approach aligns with our commitment to environmental responsibility and community well-being.

The selected odour control system involves covering equipment associated with potential odours and providing ventilation to indoor spaces. Additionally, our strategy includes the ventilation and extraction of odour gases, directing them to appropriate treatment units. The ventilation is tailored to the concentrations of generated gases, and extraction can occur either directly from the process unit (collection at the source) or through general ventilation of the building where the unit is situated.

Specifically, for the Boherbue WwTP, given its biological aerated treatment with drying sludge reed beds, we opt for a passive ventilation system. This system will be strategically employed at critical points, such as the inlet works and stormwater holding tank. Our company’s approach ensures that odour management is integrated into the design, promoting a sustainable and community-friendly wastewater treatment solution.

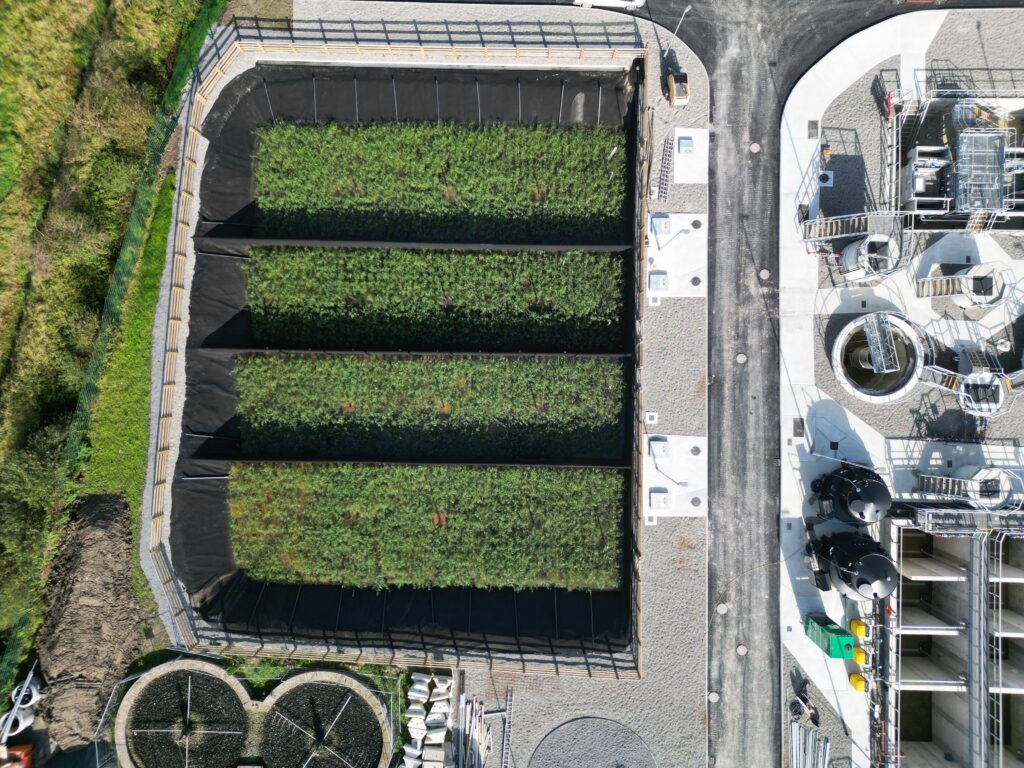

Sludge Drying Reed Beds

In Boherbue Wastewater Treatment Plant sludge reed beds were implemented to provide a viable economic alternative to sludge transport. A number of sludge reed beds have been provided in Ireland in recent years and are operating successfully. Sludge reed beds are particularly beneficial in smaller remote wastewater treatment plants, such as Boherbue, where the cost of transport of sludge to a satellite dewatering site is unsustainable.

Glanua prioritises the seamless operation of existing facilities during the project, emphasising careful sequencing to switch from current to new equipment. The commissioning plan is strategically crafted early on, ensuring alignment with the operations team for a smooth transition.

Recognising the need for substantial temporary works, our approach involves a thorough understanding of site constraints and buried services through detailed surveys. Temporary works are designed by experienced professionals and subject to rigorous review by our civil and structural consultants to ensure safety and efficacy.

Additionally, our commitment extends to the decommissioning phase, where close collaboration with operations staff is emphasised to execute the removal of existing facilities with precision and efficiency. This holistic approach reflects our dedication to operational continuity, safety, and transparent collaboration with stakeholders throughout the construction process.

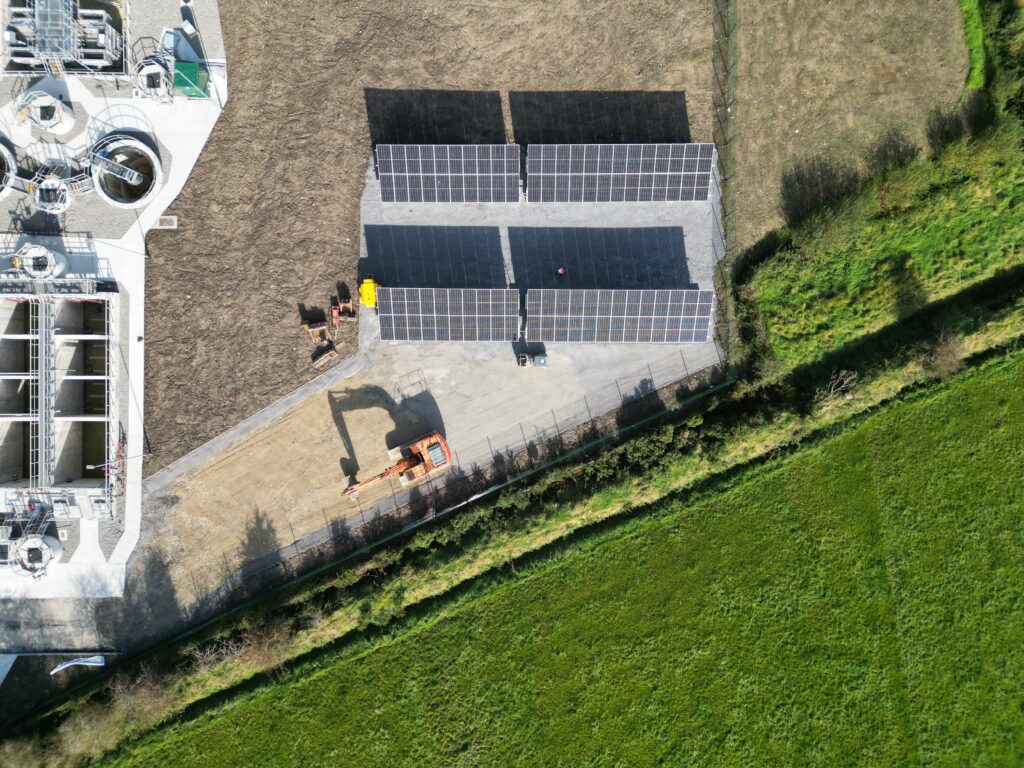

Renewable Energy – Solar Panels

A 50KW Solar panel array was installed in the plant and is used to ensure the most efficient use of grid and renewable energy. It will be limited in supplying no more than 3% export capacity to the grid

Advantages of our innovative multi-disciplinary engineering approach:

The key benefit of the Boherbue design is that Glanua created its solution using an energy-efficient design methodology, considering all options to reduce the plant’s energy needs based on the following presumptions:

- Minimise any interstage pumps, taking advantage of the existing ground topography;

- Select a nitrification/denitrification process to maximize the oxygen credit in the process and minimize chemical use;

- Extended aeration process to reduce the sludge production, minimizing WAS pumping station operation;

- Cloth filter for tertiary treatment, with low energy consumption and no TSR feed pump station required;

- Selection of sludge reed beds to minimize sludge disposal transportation, reducing significantly the carbon footprint of the treatment solution;

- Oxygen supply system design combining blowers plus diffusers, to maximize the system efficiency, taking an overall design approach instead of an individual design, to minimize energy consumption;

- Pump design selection based on the better TOTEX over 25 years, to include the energy component on the technical analysis of the solution;

- Mixers selected based on the mixing power to take a better advantage of the motor/propeller combination, based on the hydraulic mixing efficiency and to minimize energy consumption.

- Opportunity to explore the use of renewable energy sources such as solar power. A feasibility study was made before its installation in the Wastewater Treatment Plant.

The existing plant remained operational throughout the design and build process and is now ready for commissioning.