Sludge Drying Reed Beds Pilot Project

Key Information

Project Value €/£

€700,000.00

Client

Uisce Eireann / Carlow CC

Duration

18 months

Location

South East

Sector

Wastewater

Project Savings & Stats

Project Duration

Use of innovated Sludge Drying Reed beds (SDRB) in line with Uisce Eireann’s Sludge Management Plan

Cost Savings

Efficient Management of Sludge on-site, reducing Operational costs and associated Carbon Impact

Social Benefits

Reduction in transport of sludge for historical mechanical dewatering methods and using nature based solutions.

Any significant savings/efficiencies

Sludge Drying Reed beds are a cost-effective method of treatment and neutralisation of wastewater treatment bio products at source of origin

Sector

Wastewater

Project Overview

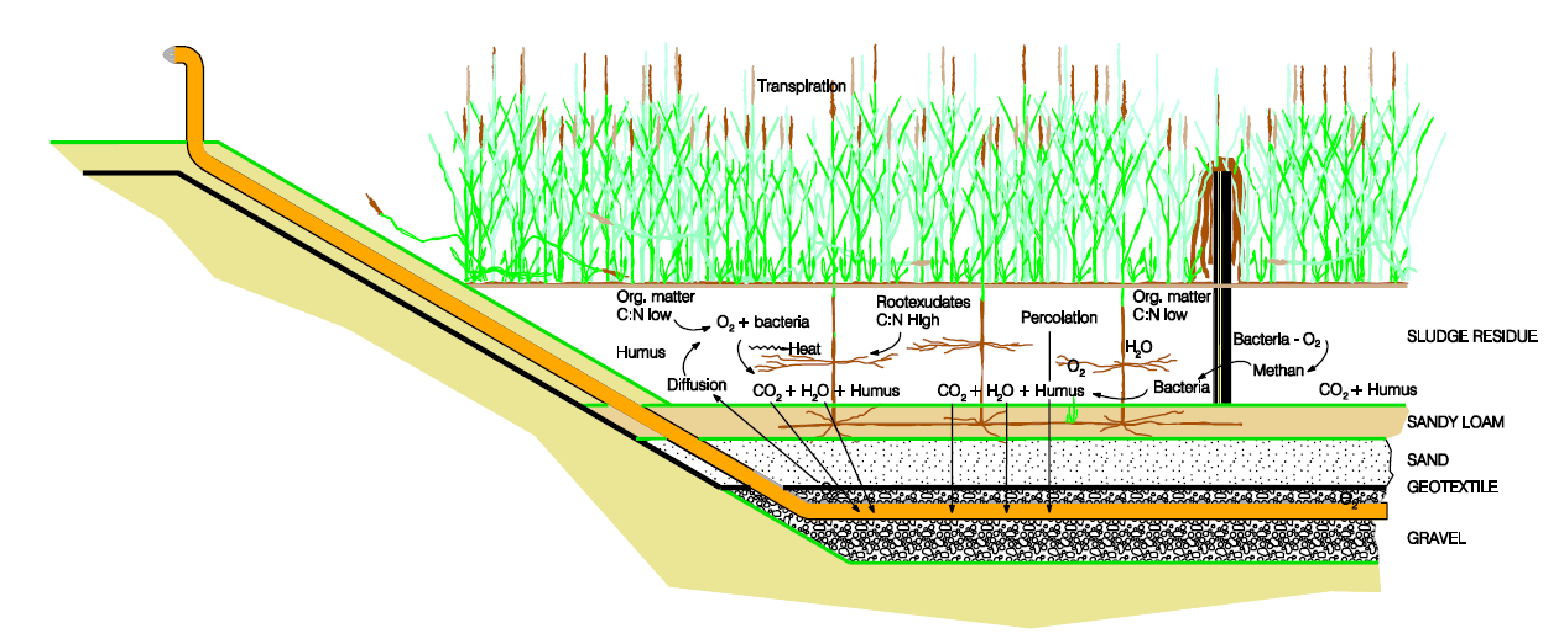

The technology and principal of the sludge reed beds is based on ability the of common reeds (phragmites australis and phragmites comunalis) to aerate the soil and through a chain of physical and chemical reaction to release water retained in soil or sludge pulp structure. In addition, reeds reduce biomass through organic growth. The process is relatively slow and dependent on the vegetation cycle of plants. It is very inexpensive and does not require power or chemicals.

Long-term sludge reduction takes place in reed-planted basins, partly due to dewatering (draining, evapotranspiration) and partly due to mineralisation of the organic solids in the sludge. From wastewater treatment plants the sludge is pumped onto the basin surface and previously dewatered sludge. The dewatering phase thus results in the dry solids content of the sludge remaining on the basin surface as sludge residue, whereas the majority of its water content continues to flow vertically through the sludge residue and filtration layers. The residue sludge’s water content is further reduced through evapotranspiration of plants.

Additionally, to dewatering, the organic solids in the sludge are mineralised, thereby minimising the sludge volume. Oxygen diffusion via filter aeration and through the cracked sludge surface and oxygen diffusion from the roots into the sludge residue enable aerobic micro-organisms to exist close to the roots and in the sludge residue. The overall reduction of the sludge volume occurs without the use of chemicals. Typically, the process involves only a very low level of energy consumption for pumping the sludge and reject water (filtrate). In cases of plants where the red beds are in close vicinity to the treatment plant the sludge may be discharged to the SDRB’s by gravity.

Long exposure to atmospheric conditions and cohabitation of worms settling in the reed beds result in the reduction of pathogens and viruses which can cause harm to humans and animals. In addition, reed beds have a value as natural habitats for birds and small animals.

The Sludge Drying Reed Beds are designed to allow for sludge accumulation over a period of 8 to 10 years depending on incoming loading. Each bed will need to be left idle to complete the dewatering cycle from the last sludge discharge (for 6 to 12 months) and emptied after this period.

The sludge will enter the beds at concentration of 0.5% to 1.5% and based on experience in similar applications will be of approx. 30% d.s. content prior to emptying of the bed. The sludge should be fully mineralised after the design period of 8 to 10 years and hence ready for use in agricultural context i.e. spread on land / composting.

Our Approach

The sludge loadings amount to a maximum of 60 kg DS/m²/year. Loading cycles are related to the sludge type and the age of the sludge reed bed system. The sludge residue will, after approximately 8 years of operation, reach an approximate height of 0.90 meter with approximate dry solids content of 30 – 40%.

The leachate from the Reed Beds system may be returned to the head of the biological treatment plant. The final biomaterial produced in the SDRB system should have characteristic similar to compost and will be of quality allowing direct application to land. The system will be designed to allow minimum sludge disposal traffic, i.e. it is envisaged the SDRB system will be emptied once per 10 to 12 years of operation and hence minimising the operational costs for the overall treatment facility.

The Major benefits of the SDRB Technology can be summarised as follows:

- Significant OPEX savings in the region of 20% of the annual operational costs of the WWTP.

- Return on investment of 3 to 4 years.

- Ease of Operation and no additional on-site labour requirements.

- The SDRB are extremely easy to operate and in the case studies above have being extremely effective in dealing with all of the sludge produced on-site. (in the case of Letterfrack and Clonbur the Reed beds have being in full operation since 2008 and no material was ever transported off-site).

- Based on the sludge loading and as outlined previously in the document the “life-span” of the reed bed can be significantly longer than 10 years if reduced loading is applied (i.e. if the WWTP are not operating at full design demand), therefore the OPEX savings can be ever higher than those outlined previously in this document.

- The SBRB’s give the operators more flexibility to deal with their sludge on-site and with no sub-contractor input/removal off-site, the operator can decant sludge to the Reed Beds as required and if process optimization measures are required that require a reduction in the amount of sludge in the system/WWTP, this can be carried out immediately and as a result the process can be instantaneously optimized with no external contractor requirements.

- Sludge reduction in the Reed beds occurs by dewatering (material sent back to the head of the works), evapotranspiration and mineralization. As the organic matter mineralizes, overall volume reduces, and it becomes part of a soil layer in which the reeds grow. The mineralized soil layer deepens with time, with the accumulation rate dependent on the solid characteristics of the sludge. Mineralized sludge typically accumulates within the system at a rate of about 10-15 cm per year. Once 1.0-1.5 m (depending on the depth of the reed bed), it can be removed can be deposed of to a suitable composting facility as a D.S. content of greater than 30% D.S. The mineralization process removes up to 25-30% of the organic matter in sludge.

- The SDRB system uses passive physical and biological processes to reduce and treat sludge, and as highlighted in point 1 above, results in significant OPEX savings not only in dealing with transportation costs but also eliminates the associated energy costs with on-site mechanical dewatering systems, such as belt presses or centrifuges. The only power consumption is pumping the sludge and return filtrate water back to the treatment plant (please note is implemented at design stage such as Clonbur & Letterfrack and proposed for Ougherard, the designer and implement the technology into the design and remove the need for any pumping requirements).

- A SDRB uses no chemicals to treat sludge, this removes the workplace Health & Safety Risks associated with use of chemicals, as well as reducing the chemical residue in the treated bio-solids that pass into the environment.

- As outlined earlier in the document, as the SDRB’s use an aerobic process no odour problems are created.

- SDRB’s have a far lower carbon footprint than other dewatering methods, especially anaerobic lagoons

- Bio-solids produced by the sludge treatment reed beds are not only dewatered, but also treated, which dramatically reduces the pathogens and vector attraction

- After treatment, beneficial reuse options for bio-solids include composting/application as a fertilizer on agricultural land. The quality of the bio-solids is better suited for use a natural fertilizer than produced by mechanical dewatering processes.

- As previously outlined, apart from the significant cost savings/return on investment, the major benefit of the systems are the increased operability of the WWTP where SDRB’s are incorporated. The filtrate water from the SDRB is treated as it percolates through the mineralized sludge layers and gravel, removing much of the organic matter present. Consequently, clean filtrate water is recirculated from SDRB back to the plant, reducing process loading within the main treatment plant, and increasing infrastructure capacity.

- In the case of the retrofitting of the SDRB technology to existing operational WWTP’s you would expect to have an increased treatment capacity from these existing facilities in the region of 5-15%.